Spencer Dock Bridge

- Engineer: Arup

- Contractor: Laing O'Rourke

- Architect: Amanda Levete

- Market Sector: Patterns & Moulds for Precast Concrete & GRC

- Product: GRP Moulds

Resembling the shape of a mantra ray and measuring 40 metres in length, Spencer Dock Bridge spans the Royal Canal and links Dublin city centre to the north docklands redevelopment area. The bridge provides a vital link for vehicles, trams and pedestrians. The complex geometry of the bridge was constructed as an in-situ two-span post-tension concrete deck edged with precast parapet units. Cordek worked on this project, providing the moulds for the precasting of the concrete parapet units.

We were very impressed with the accuracy and the finish of the models from Cordek and believe that this could only practically have been achieved using digital machining techniques.

Project Scope

The Architects at Amanda Levete considered the bridge a piece of landscape design and wanted to create a sculptural work that would integrate the surrounding infrastructure with Linear Park. The challenge was to create the complicated double curvature contoured parapets to showcase the unique design of asymmetric-shaped wings cantilevering out from the centre of the bridge deck. Cordek was approached at pre-tender stage by the Architect to discuss alternative production methods and construction solutions.

The Solution

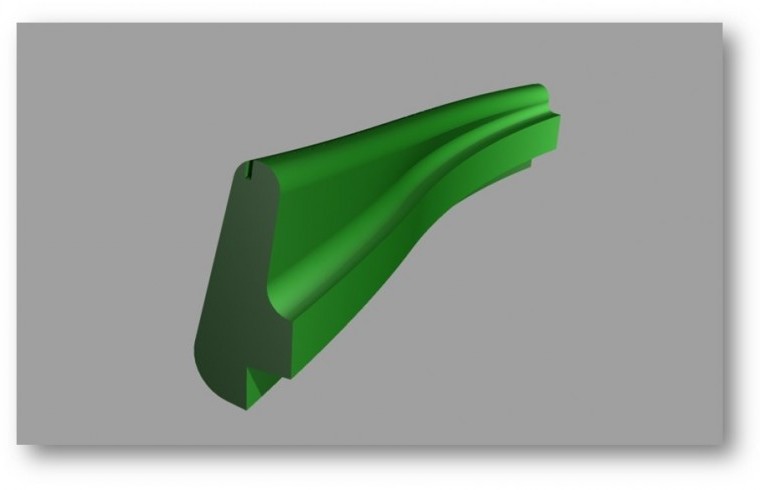

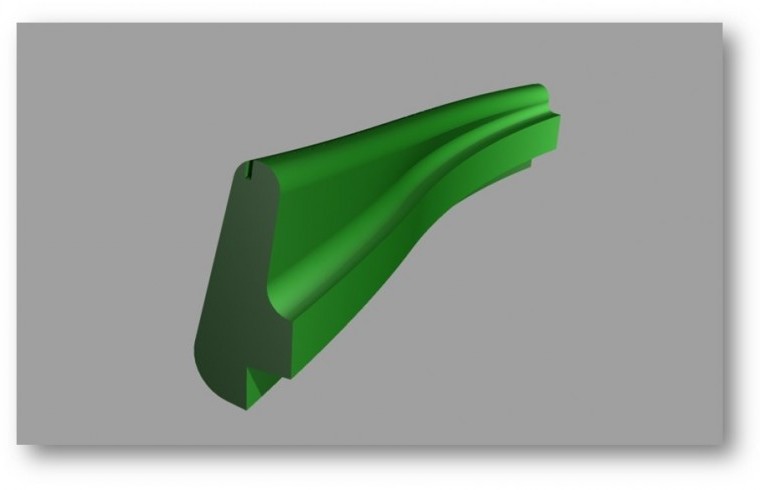

The precast elements, curved in plan and elevation, and of a continually varying cross section have an exposed fair faced finish on all visible surfaces. The solution was to cast them with inside face uppermost and to use the gap in the mould where the in-situ stitch joint reinforcement projected to place the superplasticized concrete. Constructed from a Filcor Expanded Polystyrene (EPS) profile coated with an epoxy resin and fibreglass mat, the moulds would provide a smooth tough surface that the concrete would easily de-bond from producing an excellent finish and the ability to be re-used multiple times. To avoid the presence of joints on any of the visible surfaces the moulds were manufactured in five parts.

The Process

Starting from the Architect’s 3D model Cordek created 3D drawings of the individual components that made up the former. The double curvature inner and outer mould pieces were created using a timber and plywood frame onto which Filcor EPS block was laminated. This Filcor was machined to the exact profile required on one of Cordek’s 5 Axis routers. The mould pieces were then coated in epoxy resin and fibreglass mat to create a smooth and durable surface and supplied with machined timber end faces.

Summary

The Spencer Dock Bridge received the Best Structural Design Award at the 2009 LEAF Awards. The soft geometry and asymmetry of this design has created a piece of infrastructure that is fluid in both form and function, and Cordek is proud to have been a part of this striking project.

Download Case Study PDF

Download Case Study PDF